Introduction

Hydrocarbon Leak Sensors—such as diesel, petrol, and lubricating oils—pose serious safety, environmental, and financial risks in buildings and industrial facilities. Whether it’s a generator room, fuel day tank, or chemical storage area, an undetected leak can lead to fire hazards, environmental contamination, and costly downtime.

A hydrocarbon leak sensor provides early warning, allowing facility managers to act before a minor spill becomes a disaster. In this guide, you’ll learn how these systems work, how to choose the right one, installation best practices, and where to buy them—including both premium and budget-friendly options.

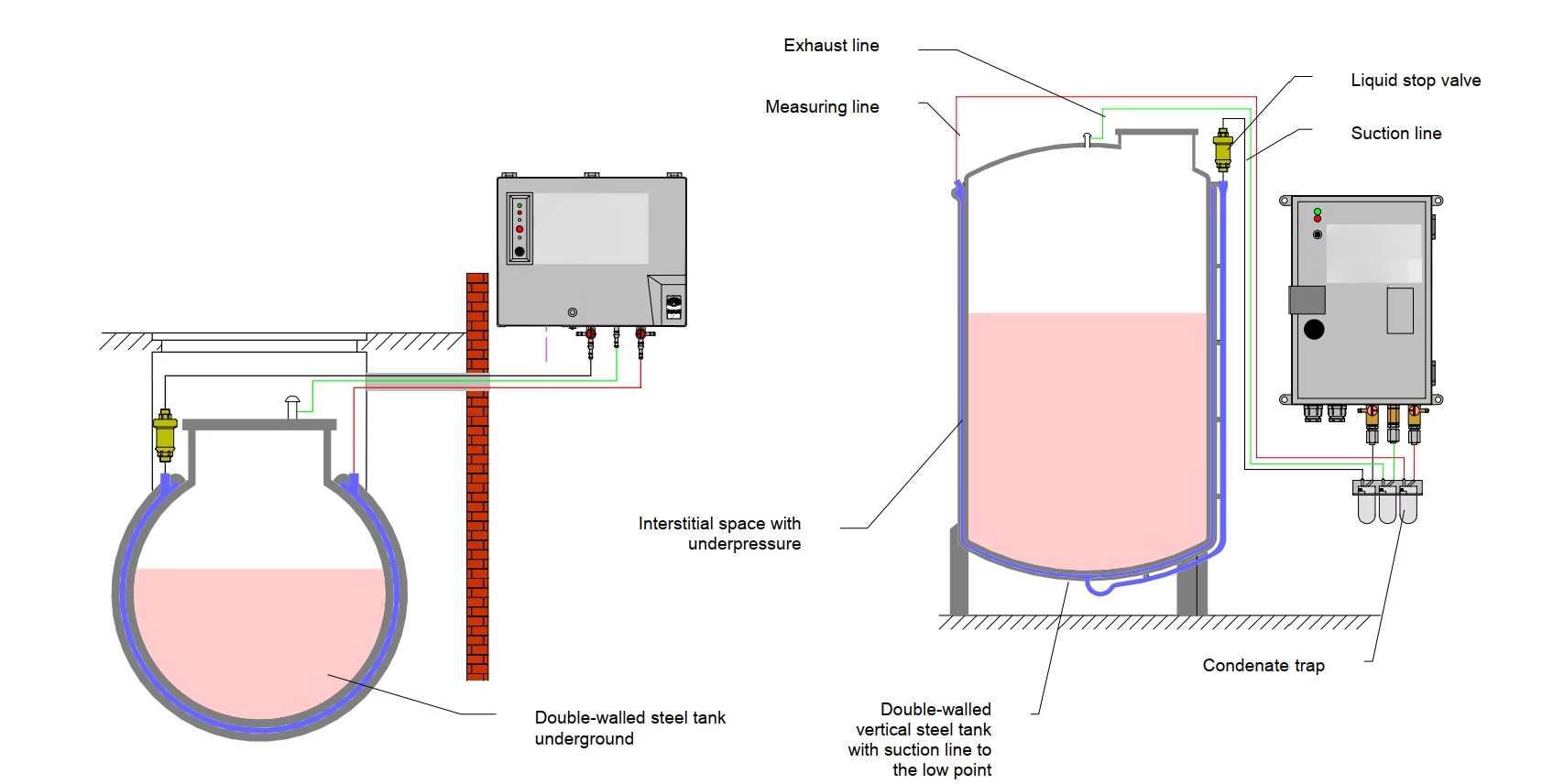

Image credits: https://www.cghnordic.com/en/produkter/

Why Hydrocarbon Leak Detection is Critical

Fire safety – Diesel and oil spills can ignite and spread quickly.

Environmental protection – Prevents soil and water contamination.

Equipment protection – Avoids damage to pumps, generators, and piping.

Compliance – Meets safety and insurance requirements in many regions.

Cost savings – Reduces cleanup costs and downtime.

How Hydrocarbon Leak Sensors Work

Hydrocarbon leak detection systems utilize specialized sensors that specifically detect hydrocarbons, while ignoring water. They come in two main forms:

1. Sensing Cable (Rope Sensor)

Detects hydrocarbons anywhere along its length.

Ideal for large coverage: fuel lines, generator perimeters, bund walls.

Selective—doesn’t false alarm from water.

Can pinpoint leak location with compatible controllers.

2. Point Sensor (Spot Detector)

Detects leaks in specific locations, such as a sump, drip tray, or low point.

Fast response for concentrated leak sources.

Often used together with cable sensors for complete coverage.

Where They’re Used

Generator rooms & day tanks

Fuel storage facilities

Chemical storage & industrial plants

Pipelines & pump stations

Marine & transport fuel depots

How to Choose the Right Hydrocarbon Leak Sensor

| Factor | Why It Matters | Recommendation |

|---|---|---|

| Coverage | Large area vs single point detection | Cable for large coverage, point sensor for small zones |

| Liquid Type | Diesel, petrol, crude oil, lubricants | Check compatibility with all used fuels |

| Environment | Indoor/outdoor, temperature, chemicals | UV, rodent, and corrosion protection for harsh sites |

| Response Time | Early warning can prevent disasters | Look for fast-acting sensors (<5 min for light fuels) |

| Integration | Link to BMS, SCADA, alarms | Choose BACnet/Modbus compatible controllers |

| Certifications | Safety approvals matter | Look for UL, FM, ATEX/IECEx for hazardous zones |

| Budget & Maintenance | Reusability, cleaning, spare parts | Reusable cables reduce long-term cost |

Installation Best Practices

Map leak risk zones – fuel lines, tank perimeters, generator base areas.

Secure sensing cables along the lowest points where liquids would flow.

Install point sensors inside drip trays, sumps, or bunds.

Label each sensor for easy location in alarms.

Integrate alarms into BMS or SMS/email alert systems.

Test regularly using approved hydrocarbon test fluids.

Clean reusable cables after real leak detection events.

Maintenance Checklist

Monthly: Visual inspection of cable routes.

Quarterly: Functional test with test fluid.

After leak: Repair source, clean/reset sensors, update logs.

Conclusion

Hydrocarbon leak sensors are not just an optional upgrade—they’re essential for safety, compliance, and cost control. Whether you’re managing a data center, hospital, or industrial plant, early detection can prevent disasters.

Investing in the right hydrocarbon leak detection system is a small cost compared to the potential losses from a spill.

Download our guide today and take the first step towards safer, smarter facility management.